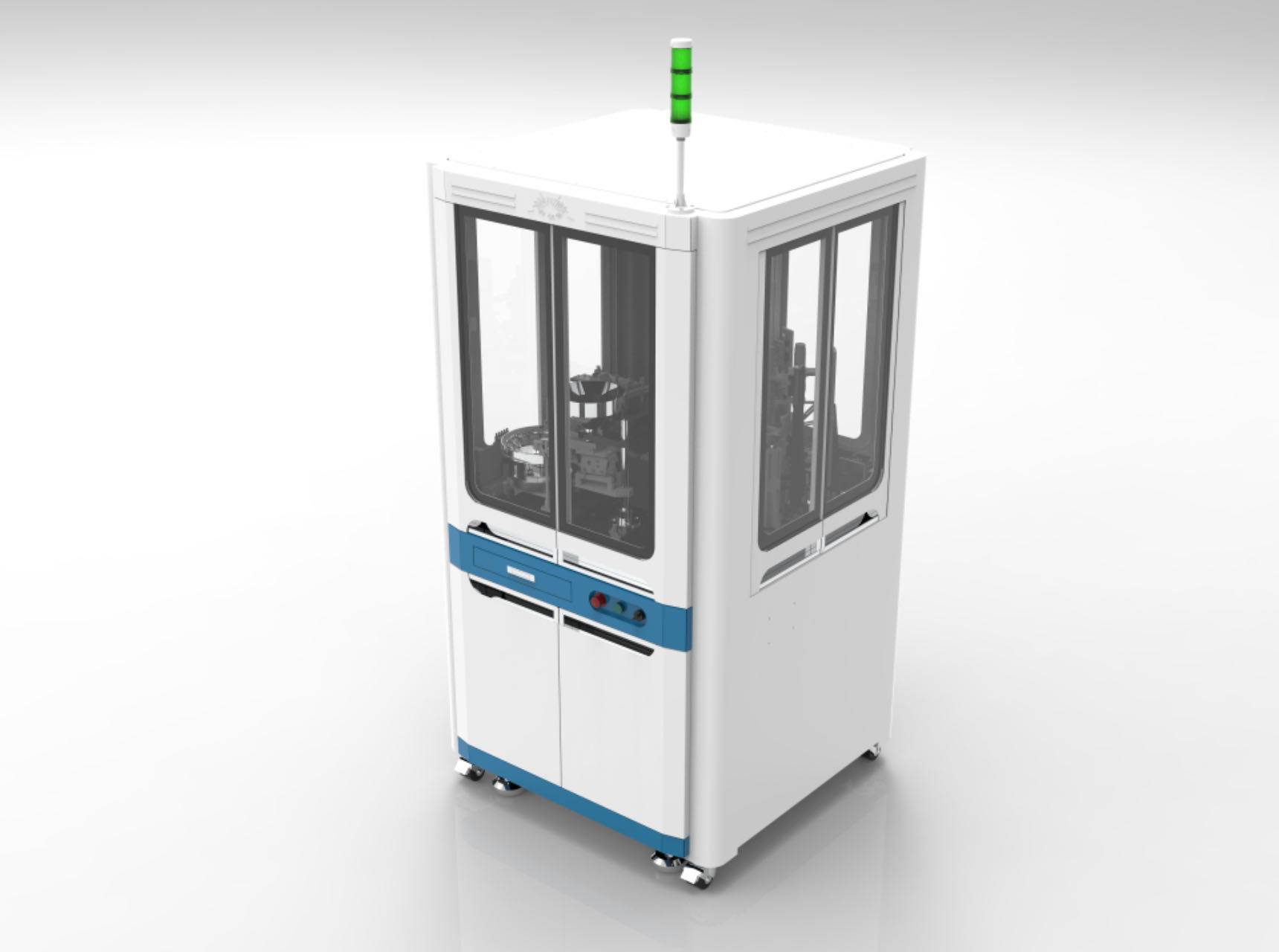

High speed visual intelligent sorting equipment is used for rapid and accurate identification of various small surface defects such as chipping,scratch,stain on magnetic cores, wafer, small electronic components, machine parts, and mechanical parts. Also, it is equiped with positive and negative recognition, classification, and monitoring of silver deficiency, small scratches, small spots, etc. Thus eliminating errors and omissions caused by eyestrain. It can set parameters. The detection specifications are unified, saving about 10 people per machine.

Currently, it has been applied in the industrial and medical industries.(( Hardware precision)): appearance inspection and selection of integrated inductors, magnetic materials, semiconductor materials, ceramic materials, mobile phone parts, hard alloys and other products. Plastic precision parts: The appearance inspection and selection process of rubber, PP (polypropylene), PA (nylon), ABS (styrene) materials and accessories. Medical category: Appearance testing and selection of products such as tablets and precision medical devices.

Size:1200*1000*1000

Detection efficiency:500~3000pcs/min